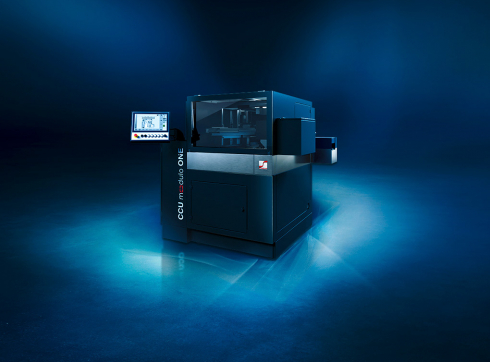

Fully-automated warehousing system

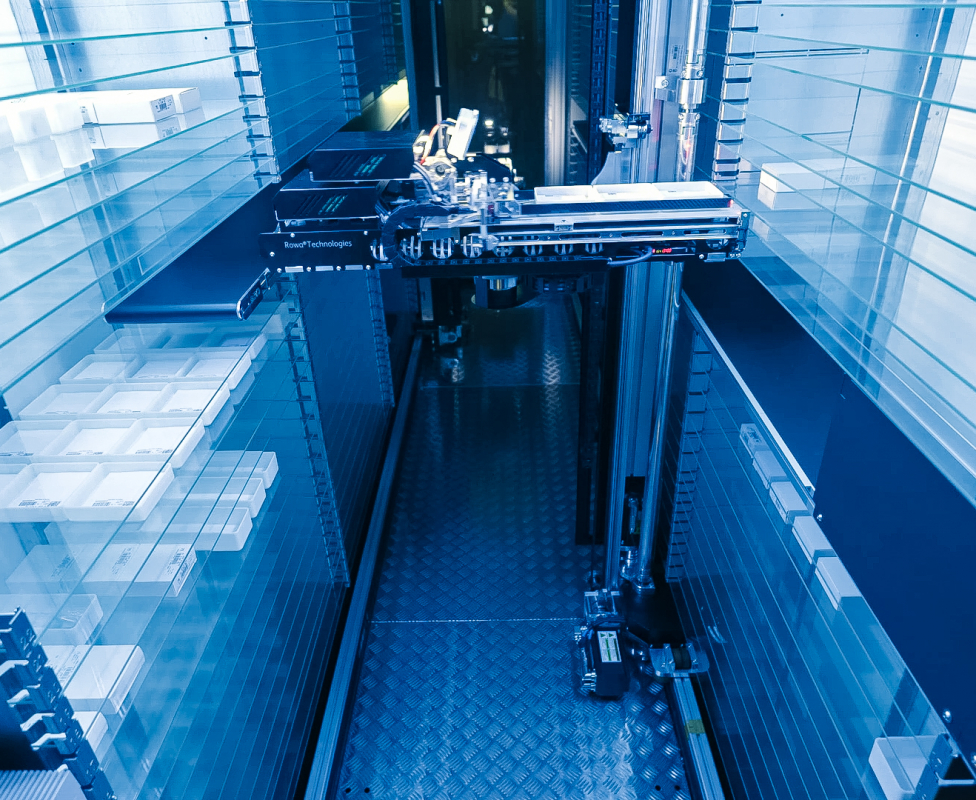

With AWS Modulo ONE, the one-of-a-kind Modulo system is extended by a fully-automated warehousing system for highly efficient and space saving storage and retrieval.

Labs now benefit from full automation all the way from warehousing to surfacing, cleaning, coating and edging – all in one fully integrated system from a single supplier.

Tap new potentials for optimization.

AWS Modulo ONE intelligently automates everyday production logistics. It reliably stores and picks semi-finished or finished lenses, frames and more directly into the job tray. Thanks to the small footprint, fast automation, and 24/7 availability, warehousing is effectively streamlined and efficiency is increased significantly.

Manual handling is reduced to a minimum, preventing human error. AWS Modulo ONE is freely configurable and can be customized specifically to meet a lab’s facility layout, capacity and throughput. Entirely scalable, it is fit to reflect future demands. Built-in redundancy guarantees there is no single point of failure. RFID technology assures unmistakable identification in job handling.

A smart automation system

AWS Modulo ONE stores and retrieves semi-finished and finished lenses, frames and more, fully-automatically and absolutely reliably – 24/7. Manual handling is reduced to a minimum and with that common errors in manual stock keeping.

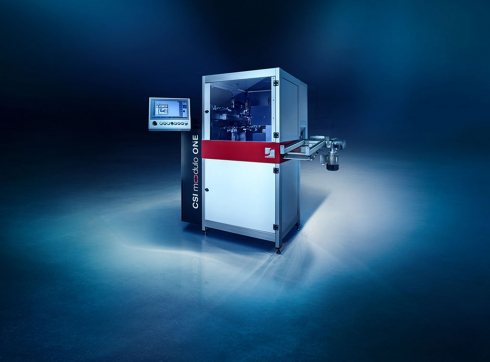

The automated warehouse system is more than a storage unit. It is a highly customizable system that can be configured to meet any requirements. Labs can freely define a layout to match their facility, the kind of items stored, the quantities, even the degree of automation, e.g. semi-automated or automatic loading. They can choose from a number of options available to design their individual solution.

Each AWS Modulo ONE is perfectly adapted and seamlessly integrated with the overall system both mechanically – through the proven conveyor components – and electronically – through the smart monitoring cockpit, the Modulo Control Center.

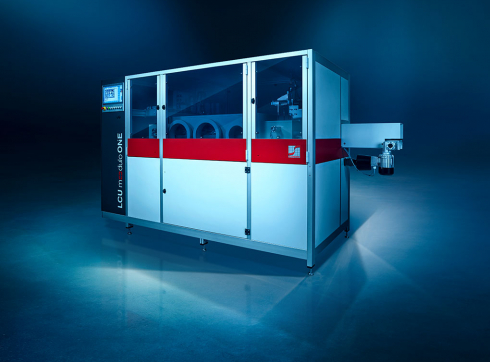

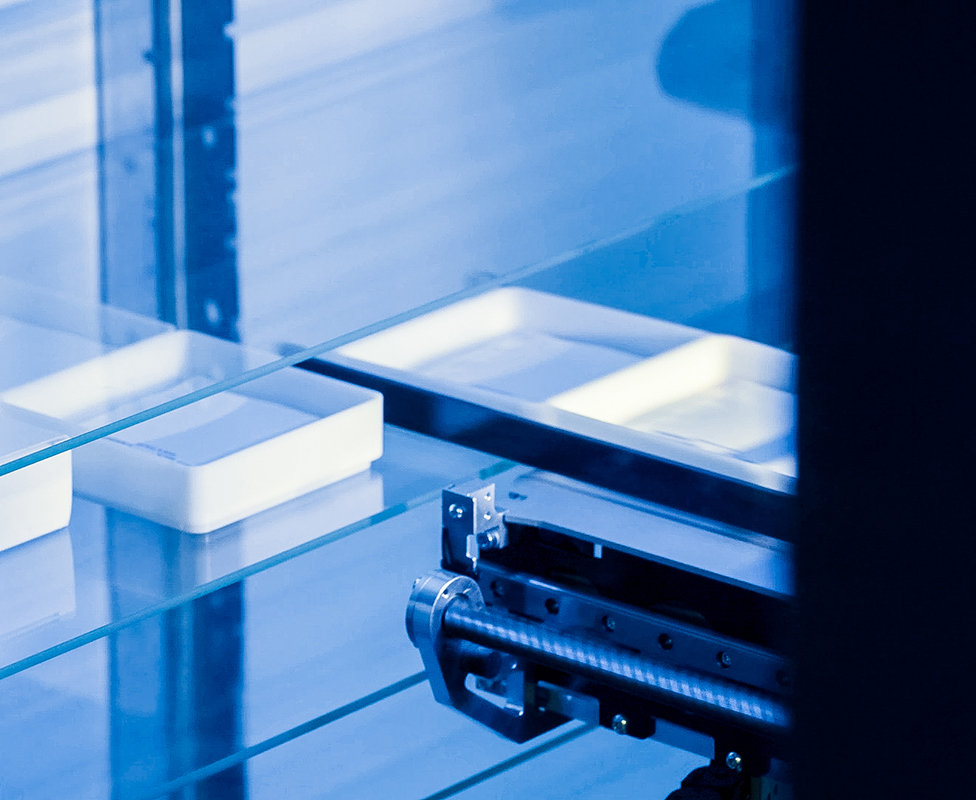

Most efficient storage

The system’s storage unit has been designed for greatest packing density. The result is highly effective storage management in a very small footprint.

To facilitate fastest picking, AWS Modulo ONE comes with a ‘fast turn’ functionality. Fast moving items are strategically stored in priority sections that allow extra fast retrieval. During slow times, the system optimizes the warehouse structure, rearranging and reorganizing items to guarantee highest picking speed during the day.

Thanks to the smart inventory monitoring, labs can keep better track of their stock.

No single point of failure,

highest reliability

To guarantee smooth and uninterrupted operation, the system has been designed in multiple sections with even distribution and redundant retrieval stations. Even if one of the components is not working, picking continues and the production is fed nevertheless. AWS Modulo ONE provides its own back up.

For highest reliability and secure identification inside AWS Modulo ONE, the system relies on RFID technology.

System components

Storage Unit – Featuring one or optional two automated picking robots handling the stored items on the shelves and managing the logistics

Optional components

Automated Loader for semi-finished lenses – Automatically feeding boxes (semi-finished lenses and frames) from a buffer belt into the storage unit

Automated Loader for finished lenses – Automatically transferring finished lenses from magazines into carrier trays that are fed to the storage unit

Semi-Automated Loader for finished lenses – Automatically transferring carrier trays with finished lenses (manually placed) into the storage unit

Semi-Automated Loader for frames – Automatically transferring carrier trays with frames (manually placed) into the storage unit

Ticket Printer feat. Folding and Insert Unit – Automatically printing, folding and inserting the corresponding job ticket into a job tray

Handling System for semi-finished lenses only – Automatically commissioning job trays with semi-finished lenses

Handling System for semi-finished lenses / finished lenses / frames – Automatically commissioning job trays with semi-finished and/or finished lenses and/or frames

The Modulo advantage

AWS Modulo ONE comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the system works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore, critical situations and downtime can be avoided before they arise. Higher uptimes and increased yields are assured.

Watch AWS modulo ONE in action!

Benefits

Fast and fully automated storage and picking

Most efficient both in terms of space and speed

Individually configured, fully scalable

Small footprint

Available 24/7

Little to no operator intervention, no human error

Closed and clean system

Supports the cognitive Modulo machine philosophy

Download

AWS modulo ONE brochure

Technical Data

Standard products can be stored in

boxes

for semi-finished lenses & frames

SCHNEIDER carrier trays - type 1 (width x depth x height)

for finished lenses & frames, tray size 96 x 96 x 22 mm (3.78 x 3.78 x 0.87 inches)

SCHNEIDER carrier trays - type 2 (width x depth x height)

for frames, tray size 63 x 156 x 37 mm (2.48 x 6.14 x 1.46 inches)

consumables in boxes or carrier trays (width x depth x height)

min. size: 15 x 35 x 15 mm (0.59 x 1.38 x 0.59 inches)

max. size: 140 x 230 x 145 mm (5.51 x 9.06 x 5.71 inches)

weight: 5 – 1,000 g (0.01 - 2.20 lb.)

All data subject to change without notice. Please verify details with SCHNEIDER.