Breaking new ground with SCHNEIDER machinery

CR Surfacing produces world-class quality lenses. In Australia, for Australia.

Looking for a new full solution partner for excellent machinery and sophisticated lens designs, CR surfacing decided to partner with SCHNEIDER in 2017.

One year later the company went green, implementing an award-winning General Waste Management System.

CR SURFACING // Melbourne, Australia

01

Competing with the big players.

Thanks to Modulo!

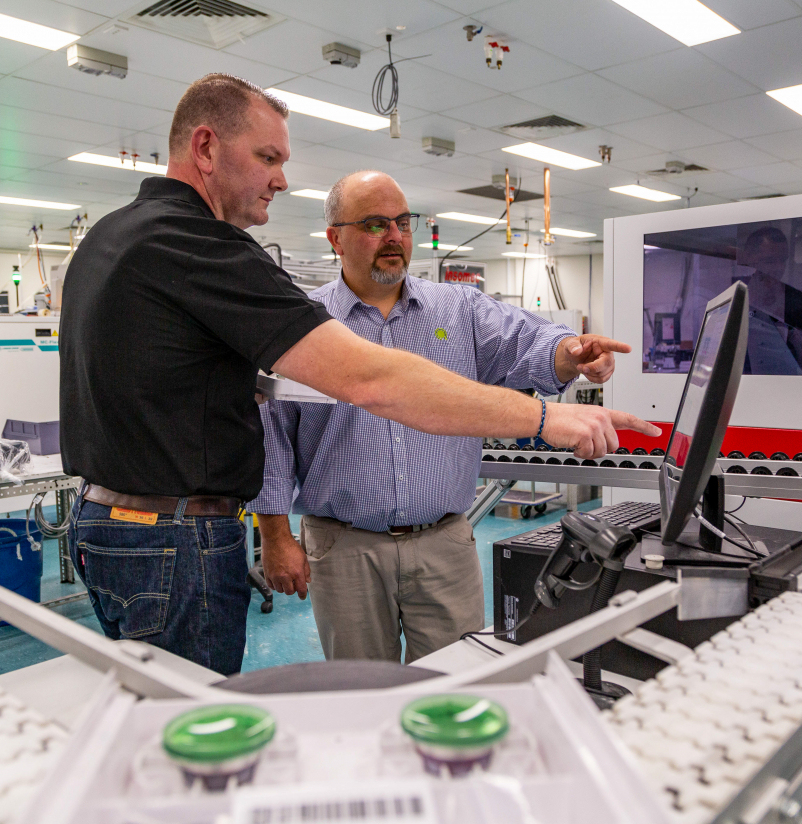

How to assert oneself on an international market dominated by multinational lens manufacturers producing in countries with cheap labour costs? This was the question of the local lens manufacturer CR Surfacing who wanted to become a key player in the Australian market.

CR Surfacing’s answer: Investing in state-of-the-art machinery to manufacture high-quality lenses and unique lens designs made in Australia.

To realize its ambitious goals, CR Surfacing changed from its previous single machine supplier to a new experienced and reliable project partner for highly integrated system solutions. In 2017, after months of investigation and deliberation, they wrapped up a deal with the German expert for fully-automated production lines: SCHNEIDER.

The entire setup of CR Surfacing’s new machine park was done in just a few weeks.

Our new lab provides the ideal conditions to produce high quality lenses. Our recent expansion into our new high-tech facility and investment in the world’s latest processing technologies demonstrates our long term interest in sustaining locally based manufacturing.

Sasha Sergejew,

National Sales Manager of CR Surfacing Laboratories

What was important to you when you decided to go with SCHNEIDER in 2017?

“Our core values revolve around innovation. Our competitive advantage lies in our ability to adapt quickly to the changing market demands and in offering the very best products you can buy. Our customers don’t compromise on quality and neither do we. For this reason, we were looking for a partner who has the same values, with future-proof upgradeable world-leading technologies second-to-none, whom we can grow together with through a trustful relationship. SCHNEIDER ticked all the boxes for us, and this partnership has been invaluable to our success.”

Eliana Varga, Executive Project & HR Manager

02

The SCHNEIDER installation -

A win-win for all stakeholders

The investment in the new lens production has paid off completely for CR Surfacing.

Along with the machine installation, CR Surfacing changed their lens design and decided to go for a new Perfection Lens Series powered by SCHNEIDER.

The Perfection Lens Series covers the most advanced range of freeform lenses. Thanks to sophisticated physiological designs combined with the most advanced manufacturing technologies the most precise and accurate lenses are manufactured. As an additional process, the high-end Accuracy Calculation allows for true tailormade experiences.

When we imagined our new laboratory, we imagined a whole new world in optics. [...] We invested millions of dollars for the growth and success of the independent market.

Adam Fletcher, Managing Director,

and Gio Troiani, CFO

How did the investment in SCHNEIDER’s Modulo Line help you to become Australia’s most favorite lens supplier?

“The cognitive machine system reduced manual handling and internal reject rates, lowering overall production costs and maximizing throughput. As a local manufacturer supplying lenses to optometry practices across Australia, we pride ourselves on quality and quick turnaround times. Our SCHNEIDER system ensures superior design replication with every lens, providing consistent premium optical quality. The installation of the SCHNEIDER Modulo Line significantly increased our efficiency, and as our business doubled in size, we were not only able to keep up with the demand, but also improve our turnaround times. The SCHNEIDER system is our guarantee for exceptional quality lenses and the most reliable service.”

Eliana Varga, Executive Project & HR Manager

03

Investing heavily to reduce the impact on

the environment

In 2018 CR Surfacing went green. Changing to biodegradable packaging materials and digital invoicing, CR Surfacing took the first steps to minimize the environmental impact on the planet. Shortly after, the company implemented an award-winning General Waste Management System. It was again SCHNEIDER that was given the task to install the new waste management solution which helped CR Surfacing to dramatically reduce its water consumption:

A pipeline system supplies clean water to the generators from the storage tanks.

A second pipeline evacuates wastewater to the Waste Management System. There, the waste gets filtered, chipped, compressed and dried. Centrifuges filter out any remaining plastic particles. The purified water is stored in tanks and returned to be reused in the generators.

The result: CR Surfacing reduced its daily demand from 2000 liters to less than 50 liters per month, saving over 500,000 liters of water per year!

lenses

per day

liters

saved per year

Watch CR Surfacing's concept to reduce its water consumption from 60.000 liters per month to 50 liters per month

Which future projects or initiatives are you up to?

“When COVID-19 hit Australia early 2020, we had the opportunity to look inwardly, reassess our position and where we want to get to. We used this time to find new sustainable solutions for our packaging and delivery systems. We moved from plastic bags to reusable soft cloth cases, fully recycled paper lens-envelopes and eco-friendly EVA (ethylene vinyl acetate) bags. We also established a charity program, in which for every completed consumer experience survey we donate a dollar to Rural Aid Australia. We also ensure that for any company event, the catering is sourced from local produce and small Australian businesses. We are always on the lookout for ways to reduce our ecological footprint and support our communities.”

Eliana Varga, Executive Project & HR Manager

About CR Surfacing

CR Surfacing is Australia’s market leading independent optical lens manufacturer, located in Melbourne, Victoria. Since established in 1976 as a small family business, history has seen the company grow to employ over 50 Australians in a state of the art environment, working with the latest technologies and cutting-edge equipment.

Never losing sight of its humble beginnings, the company’s core values remain commitment, integrity, independence and innovation.

More Success Stories

5 questions with VSP's Don Oakley

VSP Optics - We interviewed early president of VSP Optics, Don Oakley, at the inauguration of the Modulo line installation back in 2014 and 7 years later. Watch the interview to learn about his Modulo experience.

Eastern European Power-Lab

SZATMÁR OPTIKAI KFT. - The growing demand in the Eastern European and UK target markets required for Szatmár Optikai Kft. to quickly increase its production capacities. The challenge: installing a new production line next to an existing line within a few weeks.