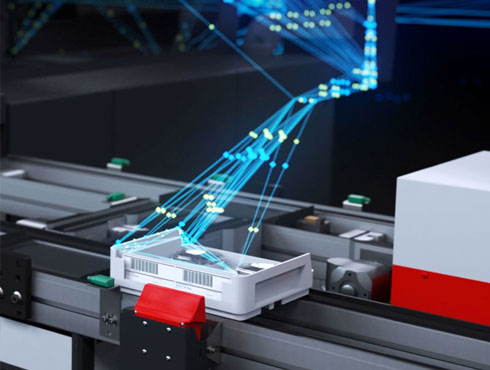

New self-organizing philosophy

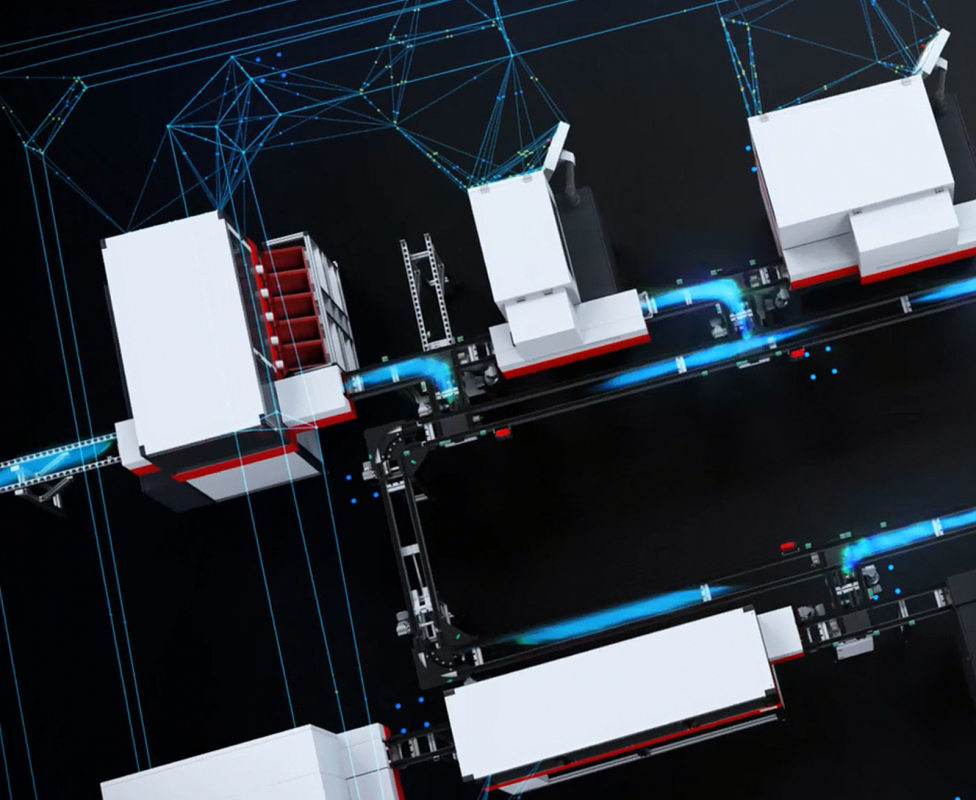

Following a new self-organizing philosophy, the cognitive machines manage the production flow all by themselves – fully self-sufficient. The result is an unprecedented level of equipment utilization in lens production and unmatched throughput. Designed for utmost flexibility, the unique arrangement and plug-and-play connection allows for the addition of new modules in any order, with minimal disruption. The Modulo Control Center seamlessly interacts with the intelligent machines and provides centralized production control. At just a glance, the smart dashboard presents the lab manager with all the key information and functions to run the lab at highest efficiency.

The Modulo Line guarantees significant cost and time savings as well as maximum equipment utilization.

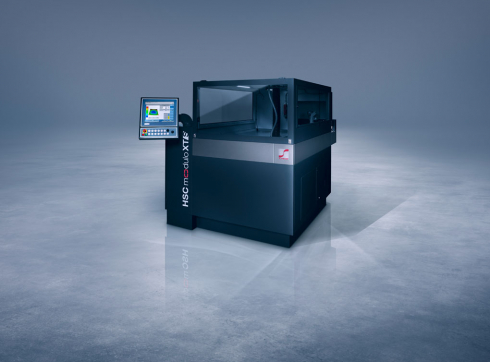

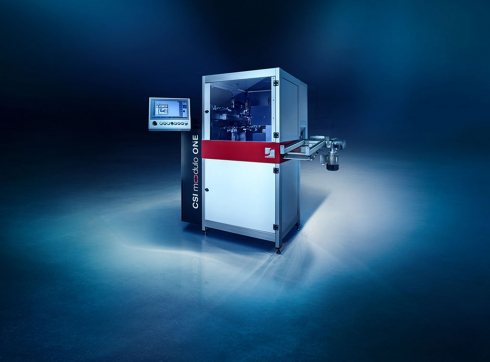

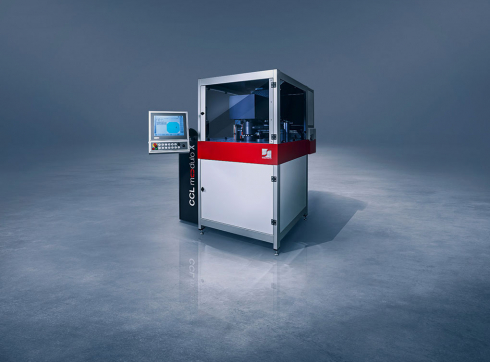

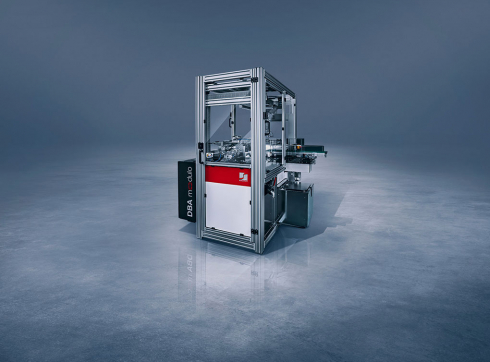

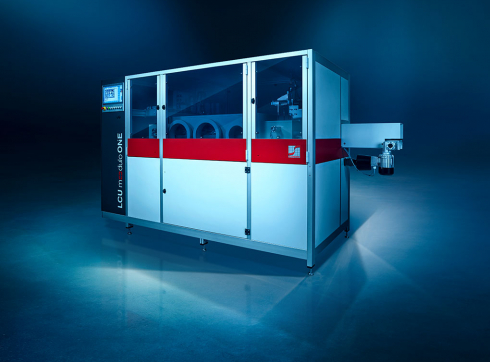

Plug-and-play value

Modulo is a series of interlinked machines that creates a highly integrated system for lens production. Designed for utmost simplicity, the machines are easily integrated into the system with plug-and-play. Thereby the system reduces the cost and complexity of traditional lab planning and the time to market. Ultimately the system allows multiple ways to integrate and grow production lines – easily expanding production capability according to individual needs.

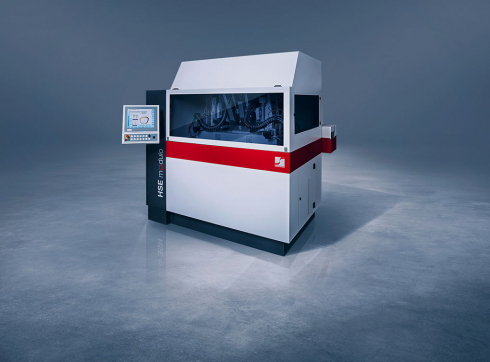

Controlling the flow

The intelligent machine software independently controls the production flow. The conveyor becomes an integral part of the machine in contrast to an external driven add-on of previous machine generations. Once a module is linked-in, the system ensures optimal utilization of the machine in a perfectly balanced production flow. Now, integration of full production lines becomes as easy as can be.

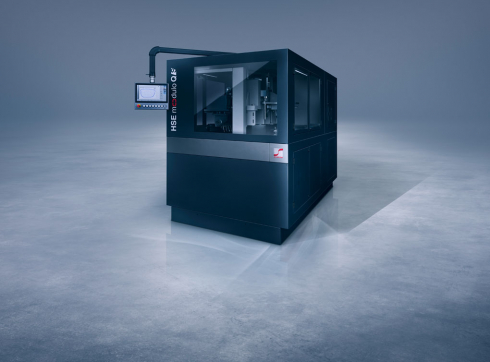

Handling all situations

The Modulo Line is a very compact and smart processing platform. Its intelligent crosslinking of machines guarantees that your production keeps going in case of an unintended stop of a single processing unit. This reduces the need for maintenance capacity and keeps the yields up.

Modulo growth roadmap

Plug-and-play simplicity provides value to all Modulo customers. The portfolio of Modulo machines will expand in the range of processing steps and performance data with the mission to meet upcoming demands. Every Modulo machine is a ticket into the future.

Managing the lab

The production is monitored and controlled with an intelligently designed management cockpit: The Modulo Control Center. It is the only MES system tailored specifically to the needs of ophthalmic production and seamslessly interacts with the cognitive machines.

The smart dashboard presents lab managers with a virtual lab overview and valuable information about the production running, e.g. machine status, efficiency reports, alerts, and preventive maintenance needs. An additional cellphone notification service gives insights on the go.

The system’s intelligent in-line quality control detects quality drifts and performs root-cause analyses for lens breakage. Systematic quality checks can be performed through a special routing functionality.

The open system allows the integration of any equipment following the VCA OMA standards.

Industry 4.0 put into practice

As the first fully-integrated lens production system, Modulo pioneered what is now called Industry 4.0 for the ophthalmic industry.

Today it is an integral part of lens production worldwide with installations in Europe, Asia, the USA, and Australia − producing thousands of jobs every hour.