THE POWER-LAB OF THE NEXT DECADE

What is it all about?

Watch our video to find out!

Why Modulo?

Discover Modulo:

The system that works for you.

Modulo. The original. The game changing system has been designed for performance and peace of mind in lens production.

It has become a vital part of the ophthalmic industry. Every day hundreds of thousands of lenses are produced on Modulo machines.

But what makes it special?

Experience the Modulo difference.

#think

Latest News

Modulo: The system that works for NVI

National Vision Inc. - James Monaghan and Sammy Bady from National Vision Inc., Plano (Texas, USA) share their experience with the peace of mind the Modulo lens manufacturing system offers, and how the SCHNEIDER CMMS and Modulo Control Center makes their life easier in daily lab operations.

Latest Launch

No. 10 & 11: Inline Coating - Finally, the time has come for our last two launches in our series of revelations shaping the Power-Lab of the Next Decade. The brand new hardcoating and rapid response coating module were premiered at DigiCON 2022 end of June.

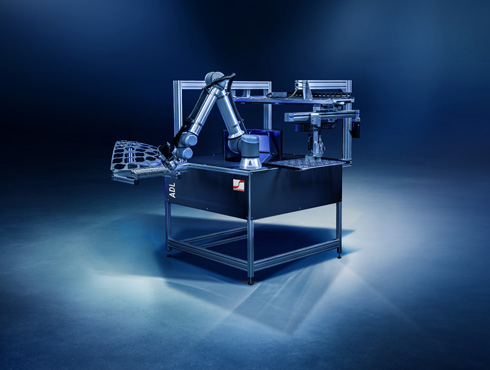

Automated Dome Loader (ADL)

No. 09: Automated Dome Loader (ADL) - With the ADL dome loader, SCHNEIDER automates batch coating for the medium-sized and larger lab, a process that used to be strictly manual. It loads, unloads and flips the lenses if both sides of a lens need AR coating. The ADL is the ideal companion to the powerful and reliable EBC coating systems.