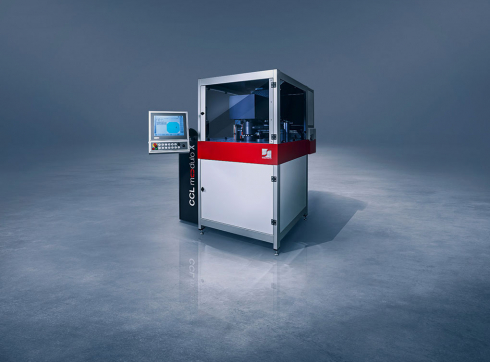

Compact fully automated stacking unit

CCS Modulo is the perfect solution for stacking job trays for curing of blocked lenses.

The full configuration is capable of stacking the throughput of several CCU blockers, making the CCS Modulo the perfect addition to the line.

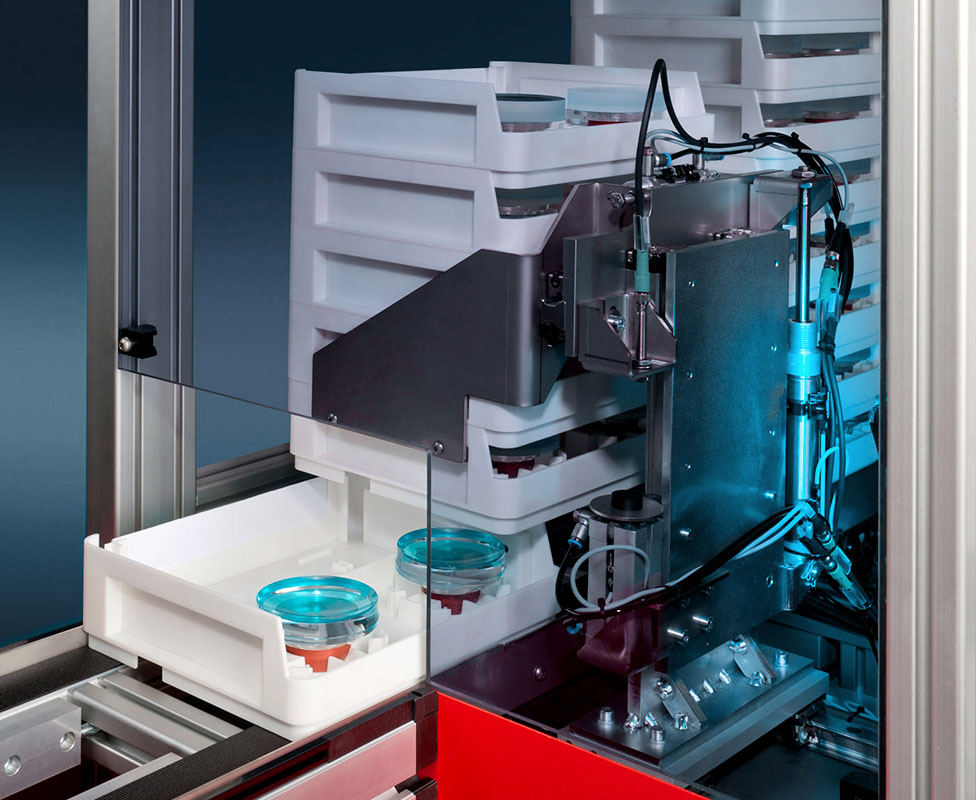

Maximum flexibility

Highly flexible and adaptable the SCHNEIDER stacker supports various different job tray formats and provides the option to adjust the curing times to your individual needs. Designed modularly, the CCS Modulo comes in different sizes – allowing you to choose the perfect size to match your capacity requirements.

The Modulo advantage

TSA Modulo comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Modulo Control Center. The lab manager is fully informed about the current status of the machine. Therefore critical situations and downtime can be avoided before they arise. Higher uptimes and increased yields are guaranteed.

Benefits

Sizes to match different capacities

Supports various tray types

Adjustable curing times

High safety standards

Connected to the Modulo System environment

Supports the new cognitive Modulo machine philosophy

Download

CCS modulo brochure

Technical Data

stacking speed

7 s/tray

throughput (avg. curing time of 30 min)

up to 140 jobs/h

controller

32-bit embedded PC

maximum stack height

592 mm (23.5 inches) resp. 10 trays

maximum capacity

70 trays

power consumption

0.3 kVA avg.

air requirement

min. 6 bar (87 psi)

machine weight

approx. 290 kg (640 lb.)

dimensions (width x depth x height)

approx. 2610 x 690 x 1720 mm (103 x 28 x 68 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.