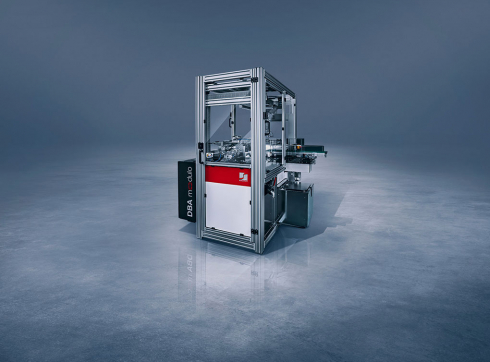

The Natural Way of Deboxing

With DBX Modulo ONE, SCHNEIDER debuts a powerful and fully automated new lens deboxer for high throughput, 24/7. The innovative technology unpacks all common kinds of boxes and materials – cardboard, blisters, even sleeves – damage-free with a clean process. It requires a minimum of energy and effort.

The novelty is that it opens all these boxes naturally: It unfolds, takes out and unwraps, entirely without ever touching the delicate lens surface but only the circumference.

Find out how exactly our DBX Modulo ONE once again realizes a step of ophthalmic lens production fully-automated and entirely hands-free.

Smart recognition and orientation

The DBX Modulo ONE is closing the gap between warehousing and surfacing to streamline deboxingfor highest efficiency. The very first step in deboxing is the error-free recognition of the box. An optical recognition system scans it to check the orientation and fully automatically identifies the brand along with the type, and contents of the box and its dimensions.

Highly versatile and capable

Once perfect positioning and alignment is done, DBX Modulo ONE, opens all common types of boxes – no matter the make and model – the way that they were originally intended to be opened:

_ cardboard box

_ cardboard box + plastic blister

_ cardboard box + foam sleeve

The system offers labs great flexibility as new boxes can be taught and the processes are adjusted accordingly by the system.

Clean and sustainable process

The flaps are wedged open and the box unfolded, before the lens is gently pushed out of the open box and the blister is taken off or the sleeve is unwrapped respectively. Without cutting the boxes, dust creation and lens contamination from cutting wheels is avoided. Equally, toxic fumes due to the colors and other

materials that must be burned when using a laser method are prevented. On the contrary, all of the steps are carried out without ever touching the delicate lens surface but only the circumference. An utterly clean process and absolutely damage-free.

Environmentally friendly

Another great benefit is that DBX Modulo ONE diligently separates the waste materials by default. No mixing materials, as the system recognizes the type and even color of the materials to facilitate effective and consistent recycling.

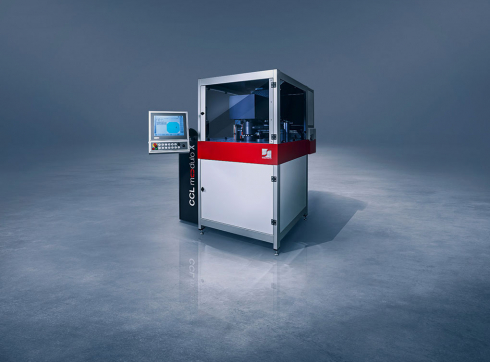

The Modulo advantage

DBX Modulo ONE comes with an on-board global interface philosophy that allows connection to the Modulo system. Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore, critical situations and downtime can be avoided before they arise. Higher uptimes and increased yields are assured.

Benefits

High throughput

Covers the widest range of boxes in the market

Low energy consumption, highly sustainable

Accurate and error-free recognition

No dust, no toxic fumes

Effective waste separation for recycling

Available 24/7

Download

DBX modulo brochure

Technical Data

box measurements (width x depth x height)

min. 68 x 68 x 20 mm (2,6 x 2,6 x 0,79 inches) max. 86 x 86 x 33 mm (3,4 x 3,4 x 1,3 inches)

box types

cardboard box, cardboard box + plastic blister, cardboard box + foam sleeve

power consumption

0,6 kVA avg.

air requirement

6 bar (87 psi)

weight machine

approx. 740 kg (1632 lb.)

dimensions without control panel (width x depth x height)

approx. 2000 x 1461 x 1790 mm (79 x 58 x 71 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.