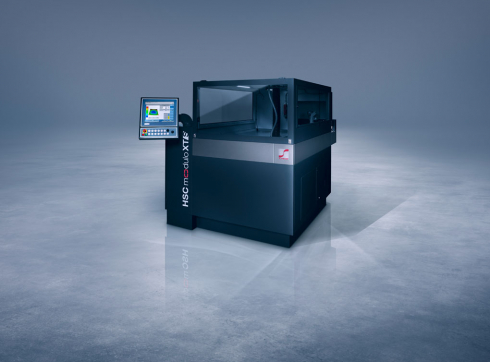

High-performance blocking

The high-performance blocker, CCU Modulo, automatically joins semi-finished blanks and block pieces with highest precision. Parallel processing steps combined with the economical use of the blocking material brings your whole surfacing operation up to speed while significantly reducing costs.

We have designed this future-proof machine with your installed machine base in mind. Compatible with today’s blocking standards and consumables, the CCU Modulo is the perfect solution to take over all of your current blocking requirements with no need to redesign the subsequent surfacing steps.

As an integral part of the Modulo concept, the CCU Modulo perfectly fits into the Modulo Line as well as into any other industry-proven Rx and freeform process.

Economical blocking

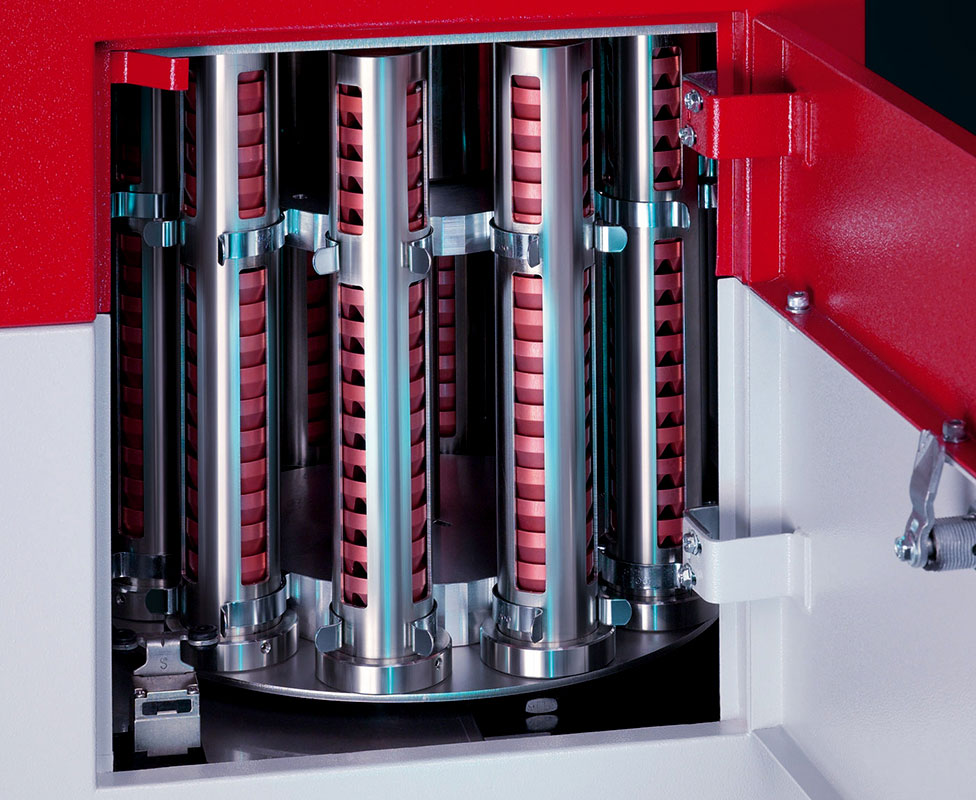

The computer controlled filling process of the CCU Modulo guarantees very economical blocking with minimized losses. A cartridge magazine enables uninterrupted processing for more than an hour. The cartridges are refilled outside of the machine resulting in no production downtime. The use of the reusable block pieces minimizes the consumption of blocking media significantly.

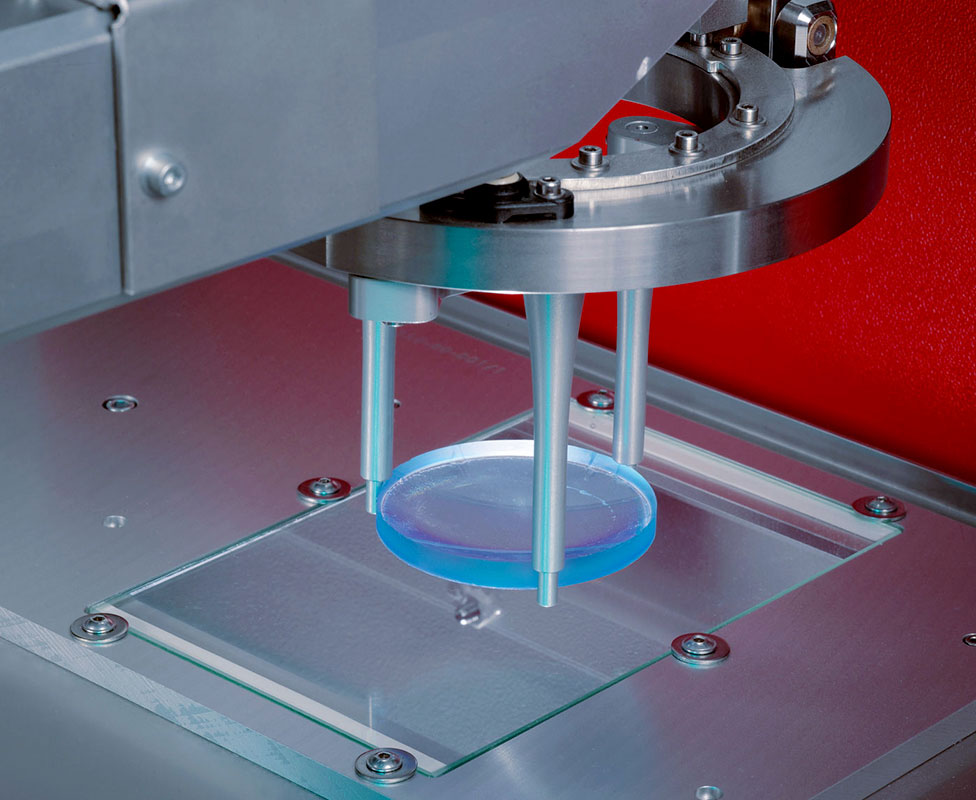

Highest precision, best surfacing results

The high-resolution optical lens recognition and alignment system guarantees a perfect position of the lens and the block piece. Unique CNC controlled prism and axis adjustment and the variable lens clamping position ensure perfectly blocked lenses no matter how complex the requirements. The result is high precision blocking and consistency over long periods of operation.

Features

— Fully automated blocking

— Three blocking stations

— Parallel lens handling, blocking and loading processes

— Camera-based lens recognition and alignment

— Prismatic blocking

The Modulo advantage

The CCU modulo comes with an on-board global interface philosophy that allows for connection to the Modulo system. Once connected to the Modulo system, the machine works as an integral part of this one-of-akind system solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore critical situations and downtime can be avoided before they arise. Higher uptimes and increased yields are guaranteed.

Watch CCU modulo in action!

Benefits

Consistent precision blocking

Fully automated operation

Highest yield

Works for single-vision, multi-focal and progressive lenses

Low running costs

Mechanical upgradeability from alloy to Connex version

Supports the new cognitive Modulo machine philosophy

Download

CCU modulo brochure

Technical Data

lens diameter

up to Ø 85 mm

lens material

all organic and mineral lens materials

blocking material

alloy

blocking diameter

53 – 63 mm

blocking height

7 – 10 mm

clamping system

block Ø 43 mm

prism angle

up to 5° (optional: 7°)

power consumption

2.4 kVA avg.

air requirement

min. 6 bar (87 psi)

machine weight

approx. 1000 kg (2205 lb.)

dimensions without control panel (width x depth x height)

approx. 1650 x 1360 x 1715 mm (65 x 54 x 68 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.