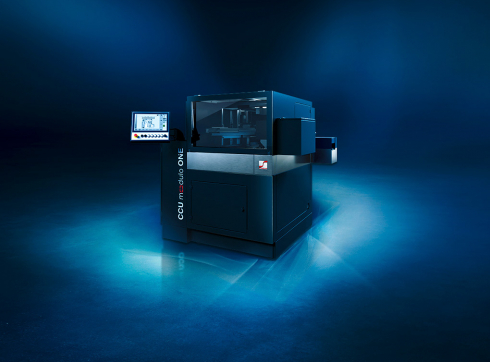

Virtually the power of two generators in ONE

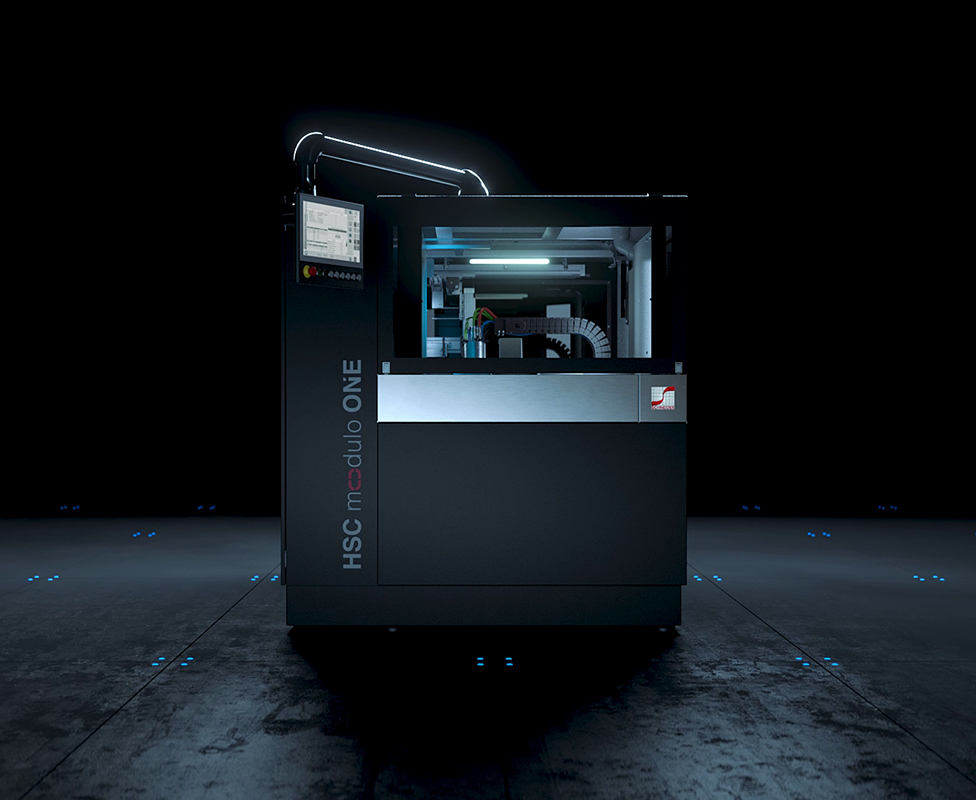

From the freeform pioneers comes a new one-of-a-kind generator that excels on every level. With an added performance of more than 50%, HSC Modulo ONE is not just a little bit better but a revolution. It is virtually the power of two generators in ONE and forms the very heart of the Power Lab of the Next Decade – Modulo ONE.

What makes HSC Modulo ONE so exceptionally fast?

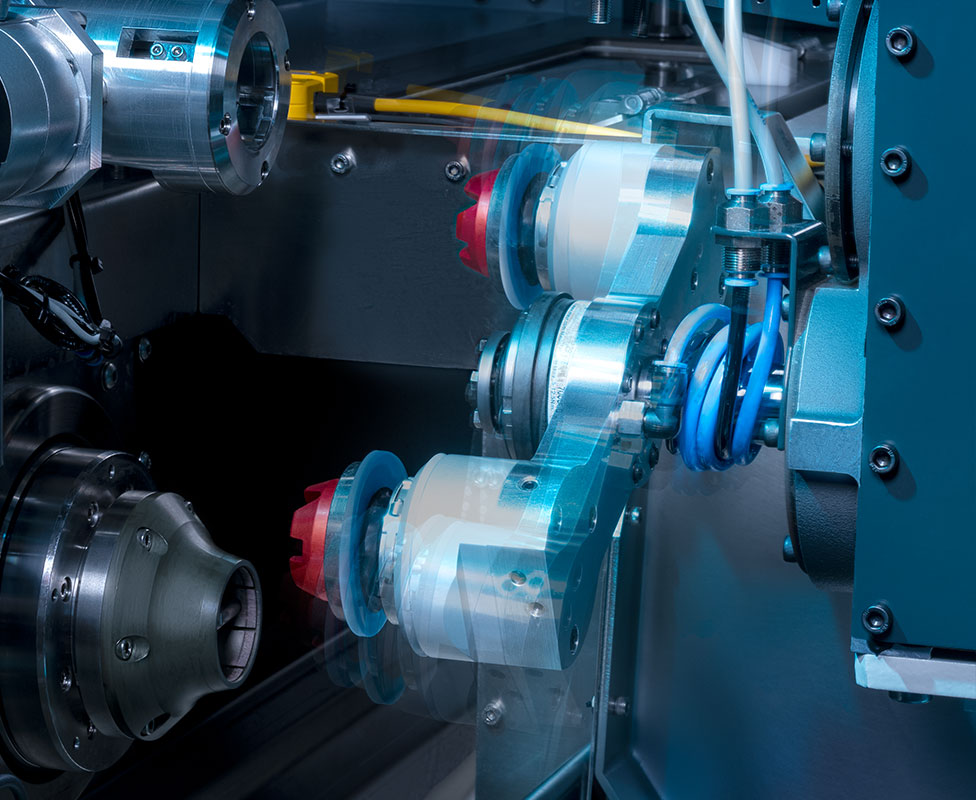

It is built on a brand new kinematic concept facilitating even faster process times. The high-performance generator relies on the proven two-motor concept featuring the most powerful XS-Tec motor for maximum dynamics and highest quality. The proven RS-Tec motor is known for its high robustness and provides added versatility.

A new ultra-fast workpiece changer transfers the lenses and facilitates shortest chip to chip times. The result is insane generating speed and performance at the same great lens quality you know from SCHNEIDER generators. Ultimately, HSC Modulo ONE provides significantly increased throughput in an even smaller footprint than before.

Get the power of two generators in ONE.

The power of

two in ONE

Where there used to be two machines, there is now just one. Labs save an entire machine, the automation and peripherical equipment to go with it.

The result is a smaller investment in a reduced space at almost the same throughput. Ultimately, labs benefit from very low cost per lens.

Entirely different kinematic concept

Since SCHNEIDER premiered the freeform technology, the HSC+G kinematics have been the state-ofthe-art in high speed cutting.

HSC Modulo ONE now breaks with the proven logic. It is the first generator that is based on an entirely different kinematic concept. It combines the two key machining elements – milling and lathe turning – in a way that they perfectly complement each other without negative effects.

Just the very best in HSC generating

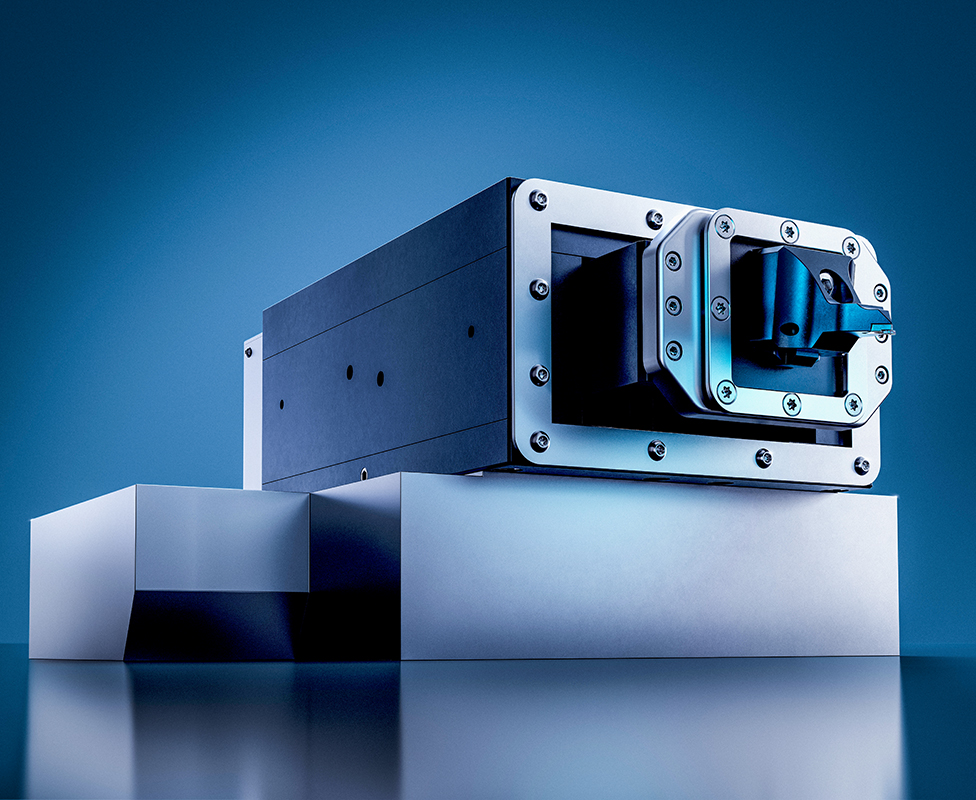

HSC Modulo ONE features the best of the best components in SCHNEIDER high-speed generating. The machine is built on an especially stiff structure that allows for highest speed processing and provides utmost process stability.

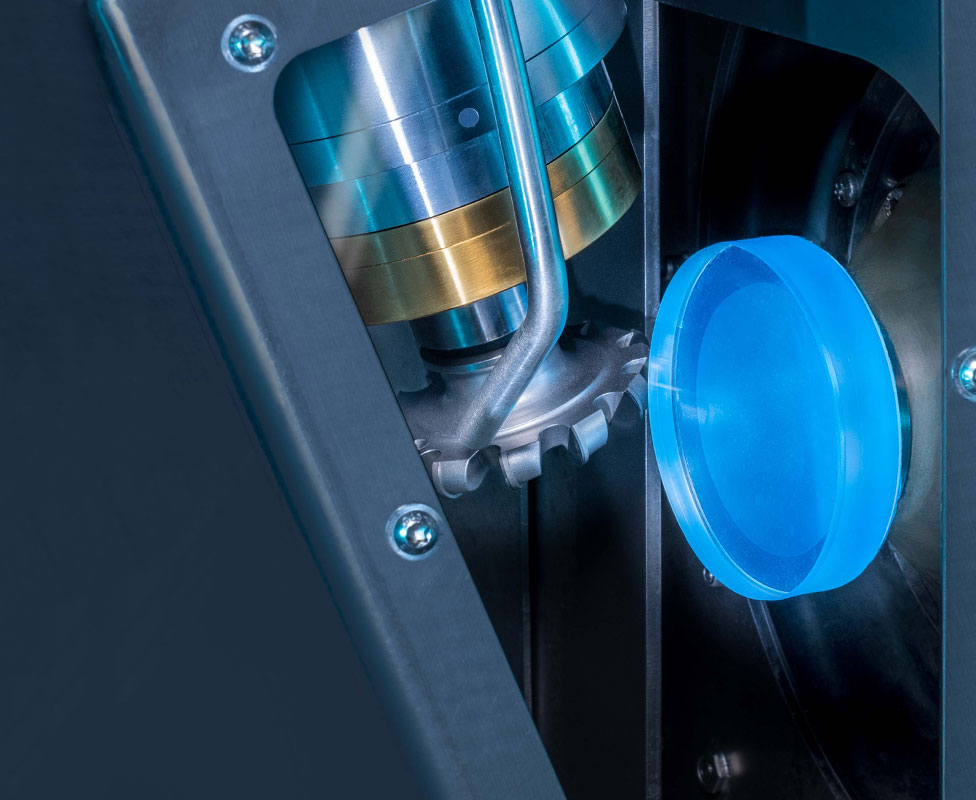

High-performance milling – The extra robust milling spindle and proven milling algorithms take care of the heavy lifting, removing the largest part of the stock at utmost force and highest rpm. The oil-mist lubricated spindle has been designed for extra longevity.

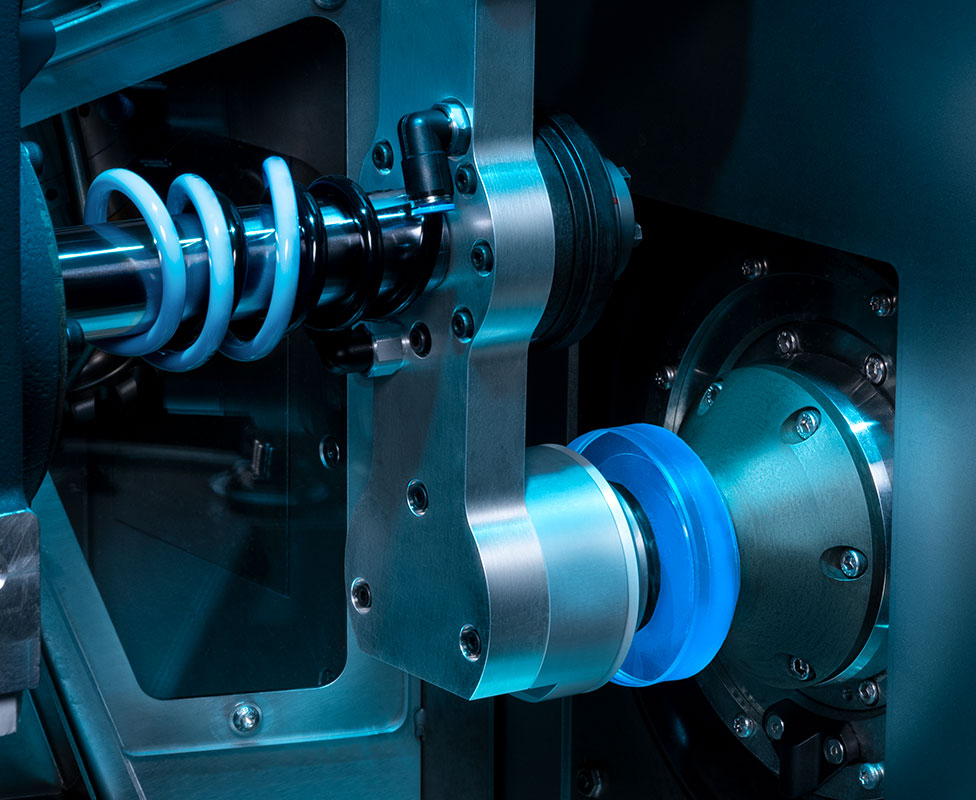

Proven two-motor concept

HSC Modulo ONE is equipped with the highly dynamic and versatile two-motor concept. The powerful XS-Tec motor is known for its exceptional acceleration of up to 40 times the gravitational speed. It supports single-tool as well as twin-tool operation. The proven and robust RS-Tec motor complements the XS-Tec motor with the proven and robust RS-Tec motor ideally.

Best individual processing combinations

Ultimately, this setup allows labs to select the perfect individual combination of milling and turning processes and ideally meets the conditions to surface even extra strong curvatures.

Labs benefit from super-fast but highly accurate movements that provide the highest surface smoothness.

The result is exceptional lens quality.

Effective swarf management

For the first time, fumes are directly extracted at the point of origin. The swarf is contained in the encapsulated chamber and managed effectively to keep the machine clean and operational.

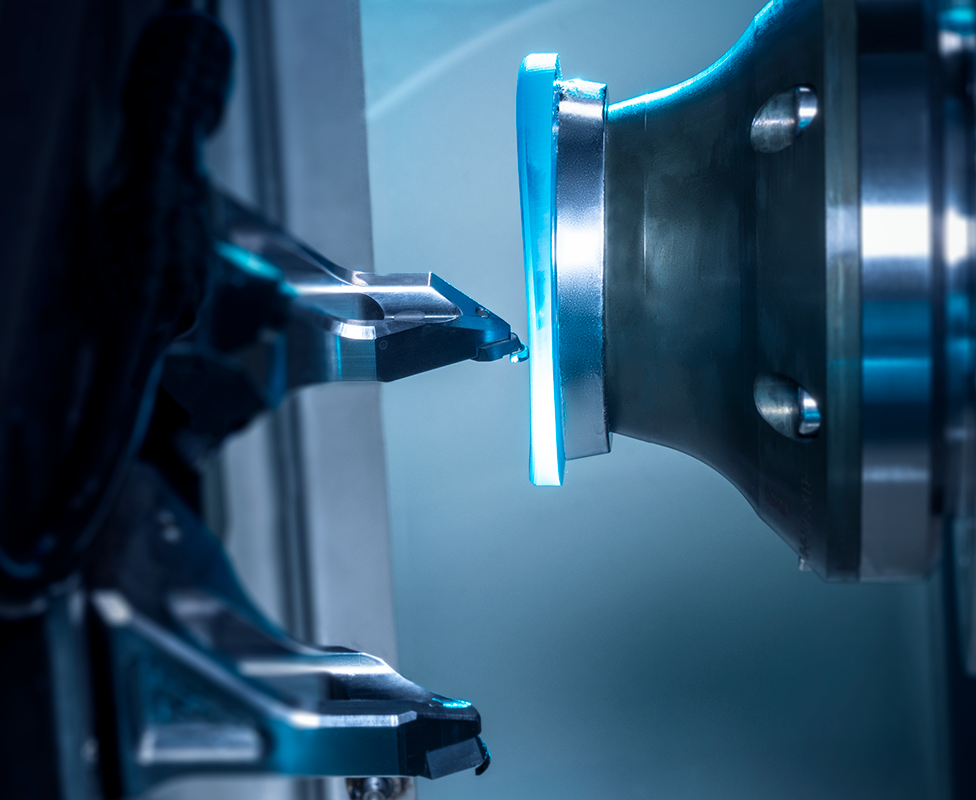

High speed workpiece changer

The lenses are transferred at highest speed with the new workpiece changer. It drastically reduces the time in between processing steps and provides the shortest chip to chip times.

Easiest upkeep and maintenance

HSC Modulo ONE has been designed based on the input of the SCHNEIDER service experts to guarantee easiest upkeep and maintenance. The result is most convenient access to all the essential components for minimum downtime.

Visual image-based diagnostics

HSC Modulo ONE is the first machine featuring 3D-visualizations for highly intuitive and interactive operation. Ideal diagnostic options for trouble shooting.

The Modulo advantage

HSC Modulo ONE comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the system works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore, critical situations and downtime can be avoided before they arise. Higher uptimes and increased yields are assured.

Watch HSC modulo ONE in action!

Benefits

Significantly higher throughput (50%+)

Drastic savings in investment and space

Lowest cost per lens

Superior design replication

Unsurpassed surface roughness

Effective swarf management

Easy upkeep and maintenance

Supports the cognitive Modulo machine philosophy

Download

HSC modulo ONE brochure

Technical Data

lens diameter

up to ø 96 mm

clamping system

block ø 43 mm

lens material

CR39, Hi-index, Polycarbonate, Trivex®

curve range

concave 0 – 14 (extendable to 30) diopters

convex 0 – 30 diopters

power consumption

12.0 kVA avg.

air requirement

6 bar (87 psi)

weight machine

approx. 3099 kg (6832 lb.)

dimensions (width x depth x height) without control panel

approx. 1685 x 2150 x 1993 mm (67 x 85 x 79 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.