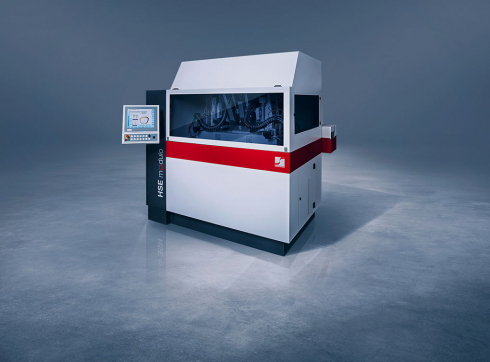

The world’s fastest edger

Meet the first and only edger on the market with four processing stations, setting a new benchmark in industrial edging.

Thanks to its unique quattro design featuring two rough cut and two finishing stations, four lenses are processed simultaneously at highest speeds for exceptional throughput. Non-productive times are reduced to a minimum through parallel processing and high speed handling systems.

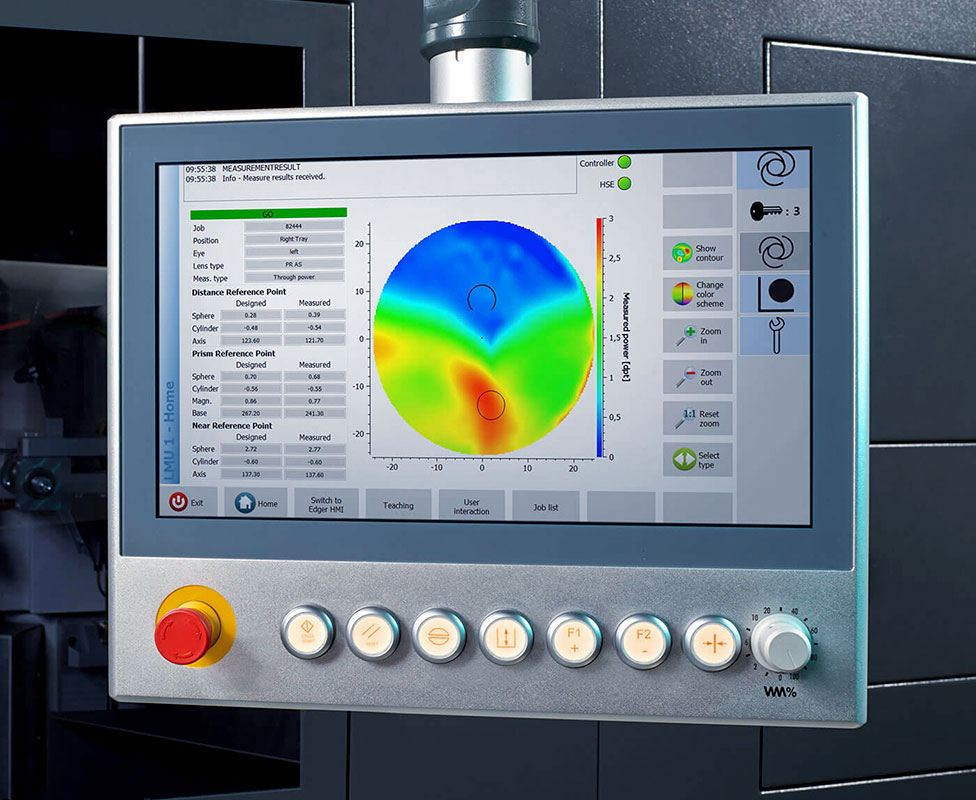

The two sophisticated LMU optical measurement units provide fully automated quality control based on the full lens map. Working blockless is a given.

Designed for unprecedented throughput

HSE Modulo QS has been designed with a single goal in mind – creating a machine that provides unprecedented throughput. This has been achieved through the unique quattro design, a cleverly devised 2×2 design comprising four cutting stations. Up to four lenses are actively cut at the same time, while another two lenses are measured and yet another four are being transferred to or back from the stations.

The powerful edger also features two tactile measurement systems, and two LMU lens measuring units. This allows for parallel processing at its best and reduces non-productive times to a bare minimum.

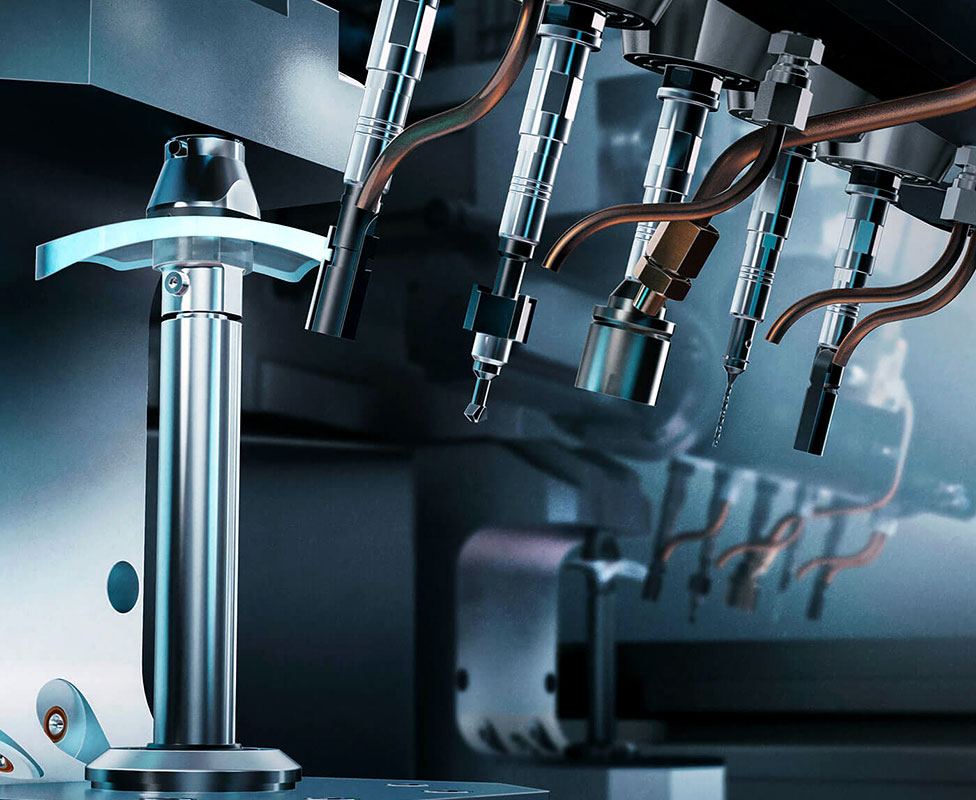

Four processing stations, no tool changes

Substantial time is saved by deploying multiple spindles and eliminating tool changes. Each rough cut station is equipped with a high-frequency milling spindle to cut the rough shape at high speed. The finishing stations are fitted with five tool spindles mounted next to one another. Consequently, instead of changing tools, HSE Modulo QS has all the tools available for immediate utilization. In fractions of a second the next finishing step starts, resulting in extremely short chip-to-chip times.

To provide the rigidity required for high-speed edging with precision and smoothest edge quality, the HSE Modulo QS’s axes are mounted on solid cast iron blocks. Separating the working chambers for cutting and measuring ensures that swarf is contained and the lens measuring units remain clean.

Highly sophisticated shape optimization

The HSE Modulo QS is prepared to keep up with the constantly changing requirements of fashion. The advanced Shape Editor offers simple programming of virtually any shape, even the most complex. The sophisticated software performs all optimizations including 3D-fit fully automated to provide the best results without specific operator expertise.

Excellent aesthetics

The sophisticated set of rules for auto bevel positioning produces better aesthetics with all common and complex jobs. Together with the automated size adjustment, best fit with superb aesthetics is guaranteed.

Built-in quality control

In addition, the fast non-tactile measurement technology measures the spherical and cylindrical power, axes and prism to determine the right lens position. Alternatively, the system recognizes visible and semi-visible marks and printings. Working blockless, the edger reduces costs and eliminates handling errors.

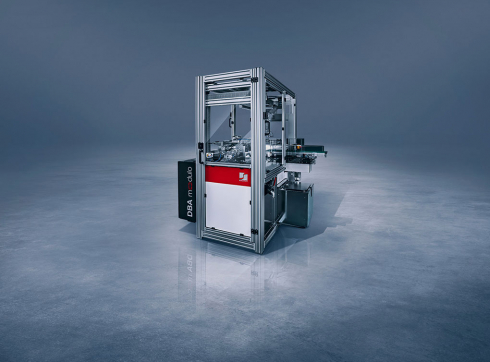

The Modulo advantage

The HSE Modulo QS comes with an on-board global interface philosophy that allows for connection to the Modulo system. Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind system solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore critical situations and downtime can be avoided before they arise. Higher uptimes and increased yields are guaranteed.

Watch HSE modulo QS in action!

Benefits

Best first-fit rate and highest throughput

Robust machine design

Integrated quality control with LMU

Intuitive, simple to use shape editor

Broad range of finishing options

Premium polished edges

Blockless handling

Supports the new cognitive Modulo machine philosophy

Download

HSE modulo QS brochure

Technical Data

lens diameter

up to Ø 85 mm

lens thickness

up to 25 mm

lens material

CR39, Hi-index, Polycarbonate, Trivex®, Tribrid™

minimum B-size (depending on the used block piece)

approx. 22 mm

power consumption

6 kVA avg.

air requirement

6 bar (87 psi)

machine weight

approx. 2750 kg (6063 lb.)

dimensions without control panel (width x depth x height)

approx. 1650 x 2950 x 2225 mm (65 x 117 x 88 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.