High performance

alloy-free thin film blocking

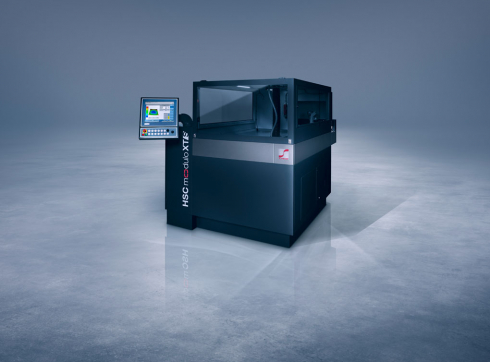

With the development of the alloy-free and high-performance thin film blocker, CCB Modulo, SCHNEIDER demonstrates its investment in green sustainable technologies. The groundbreaking innovation meets the rising requests of an economical, sustainable and environmentally-friendly production.

Parallel processing steps combined with an intelligent block piece concept and highly accurate positioning of the lens ensure lowest costs as well as high quality and stability. Even high prisms can be processed with the brand new and powerful Eco-Fuse Technology (EFT).

Another highlight is the full freedom to use any blank type on the market which makes the CCB Modulo the perfect solution to satisfy all blocking requirements.

Perfect task coordination,

parallel processing

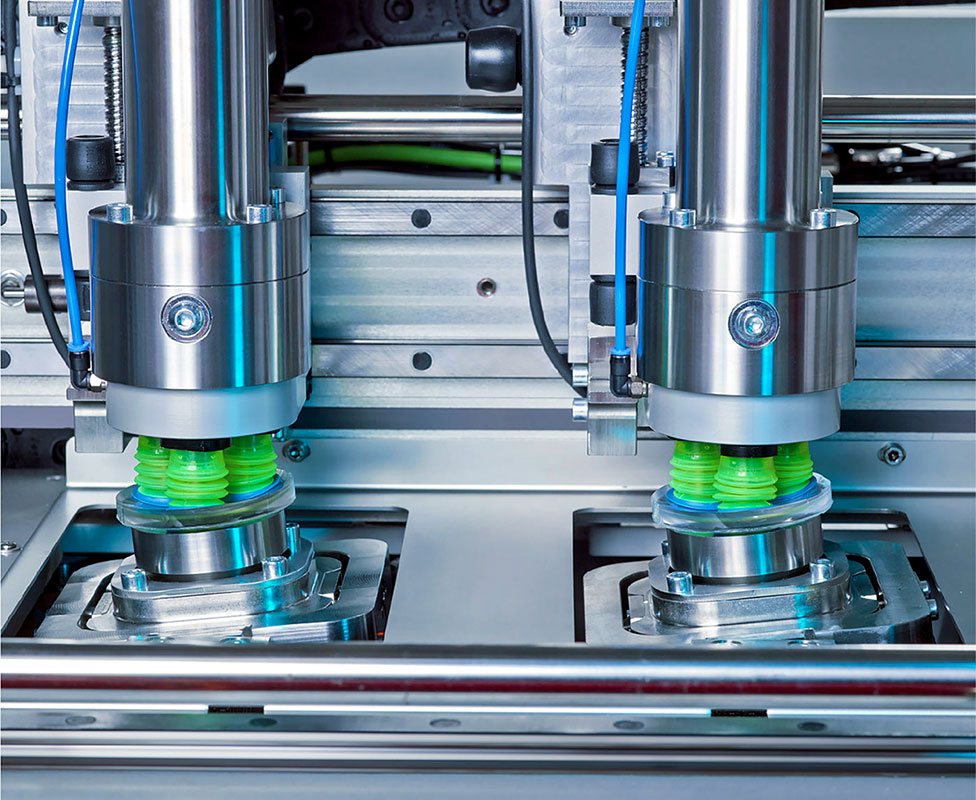

Lens pick up, lens measurement, block piece supply and media application are placed in a parallel and easy accessible configuration. A high-resolution optical lens recognition and alignment system guarantees perfect positioning of the lens and the block piece. The process flow is managed by independent handling systems for lens and block piece pick up, lens alignment and feeding of the block stations. While the first pair of lenses is processed, the next lenses are already loaded and precisely aligned before they meet their block piece counterparts.

High prism capability

SCHNEIDER’s unique CNC controlled prism and axis adjustment together with a very high mechanical stability enable lens positioning with maximum accuracy. Another highlight is the intelligent block piece concept consisting of a highly robust metal piece and a pre-shaped plastic part which can be exchanged. The stable and reusable block pieces guarantee cost reductions and blocking material savings. No matter how complex the requirements, the EFT system ensures high precision blocking and consistency.

Economical blocking without block rings

Compared to other blocking systems using different block ring sizes, the CCB Modulo features a new and flexible CNC blocking concept without the need for block rings. While block ring based machines suffer from the need for continuous block ring changes leading to high production losses, the CCB Modulo ensures continuous machine utilization.

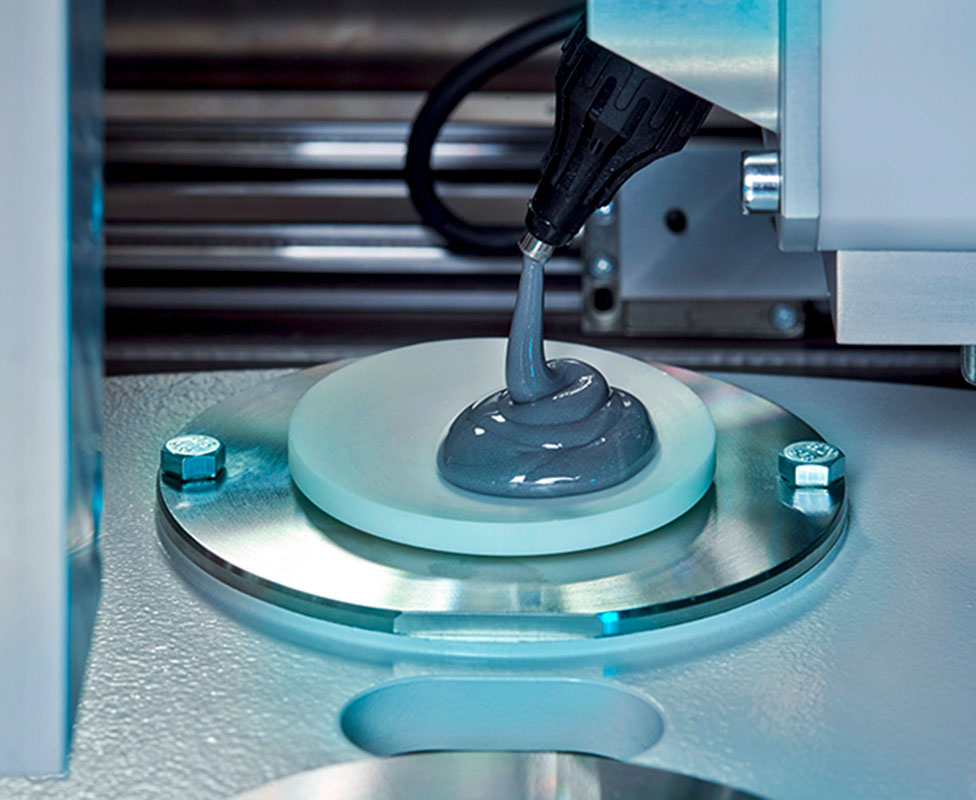

Sustainable alloy-free blocking

Years of experience helped SCHNEIDER to create a new and patented formulation. The environmentally friendly thermoplast guarantees optimal performance by uniting all important requirements like stability, adhesion, temperature behavior and deblocking on demand.

An intelligent algorithm calculates the required material amount for the thin film blocking which is applied on the block piece.

Features

— Fully automated Eco-Fuse Technology (EFT) blocking

— Intelligent blockpiece concept

— Blocking without block rings

— Parallel lens handling, blocking and loading processes

— Camera-based lens recognition and alignment

The Modulo advantage

CCB Modulo comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore, critical situations and downtime can be avoided before they arise.

Higher uptimes and increased yields are guaranteed.

Benefits

Consistent precision blocking

Fully automated operation

Sustainable production – no toxic waste

Highest yield

High performance patented thermoplast

Very little material consumption

Works for single-vision, multi-focal and progressive lenses

Low cost of ownership compared to other non-alloy solutions

Supports the new cognitive Modulo machine philosophy

Download

Whitepaper: pros & cons of UV free plastic blocking technology

Download

CCB modulo brochure

Technical Data

lens diameter

up to Ø 85 mm

lens material

all organic lens materials

blocking material

EFT

clamping system

block ∅ 43 mm

prism angle

up to 6°

power consumption

2 kVA avg.

air requirement

6 bar (87 psi)

machine weight

approx. 1000 kg (2205 lb.)

dimensions without control panel (width x depth x height)

approx. 2220 x 1340 x 1915 mm (88 x 53 x 75 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.