No bubbles, wrinkles,

or detaching – even with extreme lenses.

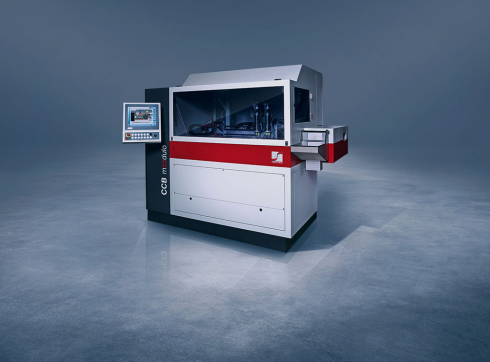

The fully automated spin protection system, SPP Modulo, optimally protects lenses during surfacing utilizing UV-curable liquid protection layers. Problems with wrinkles, bubbles or detaching, commonly known with current taping solutions, are a thing of the past. Ideal preconditions for autoblocking.

Spin-protection replaces tape

The UV-curable protection layer is evenly distributed across the lens optimally covering it while adhering tightly to it – even with extremely curved lenses or extreme flat top bifocals. Bubbles or wrinkles are prevented that often result in power or cosmetic defects.

One filling of the lacquer tank lasts all shift long and can be refilled quickly and easily, resulting in uninterrupted processing and minimum downtime. No hassles with tape replacement.

Tape vs. spin protection

After processing, the protection layer can be removed easily with SCHNEIDER’s solutions for deblocking and tape-stripping.

Besides surfacing protection, this new spin protection technology can also be used for ideal protection of blanks and semi-finished goods at different stages such as storage or transportation.

On the left: Bubbles and detaching – common problems with tape

Right side of lens: An evenly distributed layer of lacquer optimally covers the lens.

The Modulo advantage

SPP Modulo comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Control Center. The lab manager is fully informed about the current status of the machine. Therefore, critical situations and downtime can be avoided before they arise.

Higher uptimes and increased yields are assured.

Watch SPP modulo in action!

Benefits

Fully automated lens protection

No bubbles, wrinkles, or detaching – even with extreme lenses

Uninterrupted processing all shift long

Fast and easy lacquer refill

Ecological solution resulting in significant waste reduction

More cost effective than tape

Designed for Modulo Control Center integration

Download

SPP modulo brochure

Technical Data

lens diameter

up to Ø 85 mm

lens material

CR39, Hi-index, Polycarbonate, Trivex®

lacquer tank capacity

1l (33.82 fl.oz.)

curing method

UV LED

power consumption

2.3 kVA avg.

air requirement

min. 6 bar (87 psi)

machine weight

approx. 500 kg (1103 lb.)

dimensions without control panel (width x depth x height)

approx. 1560 x 1351 x 1715 mm (62 x 54 x 68 inches)

All data subject to change without notice. Please verify details with SCHNEIDER.