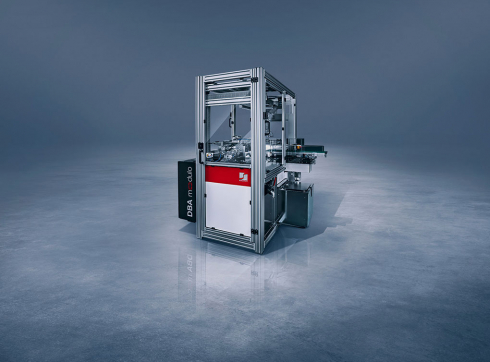

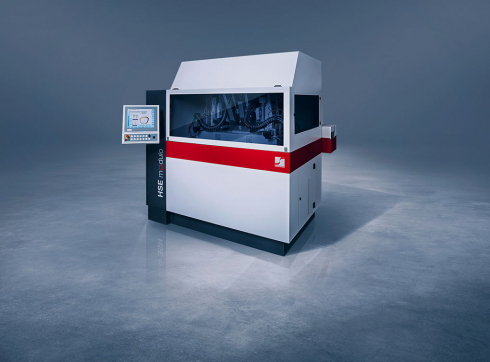

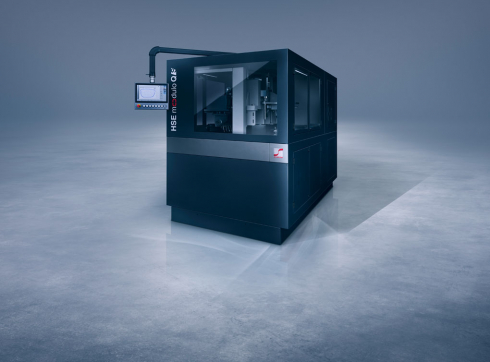

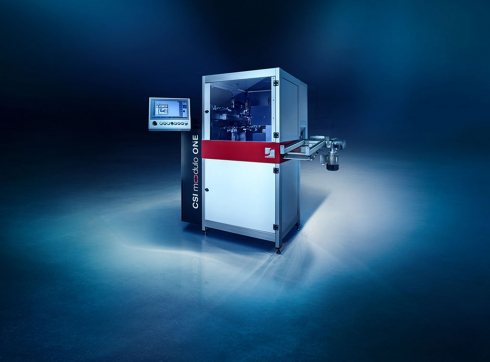

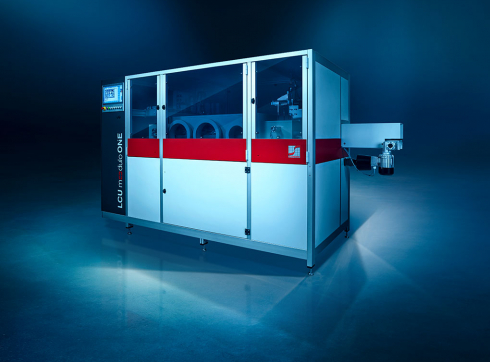

Highest throughput meets smallest footprint

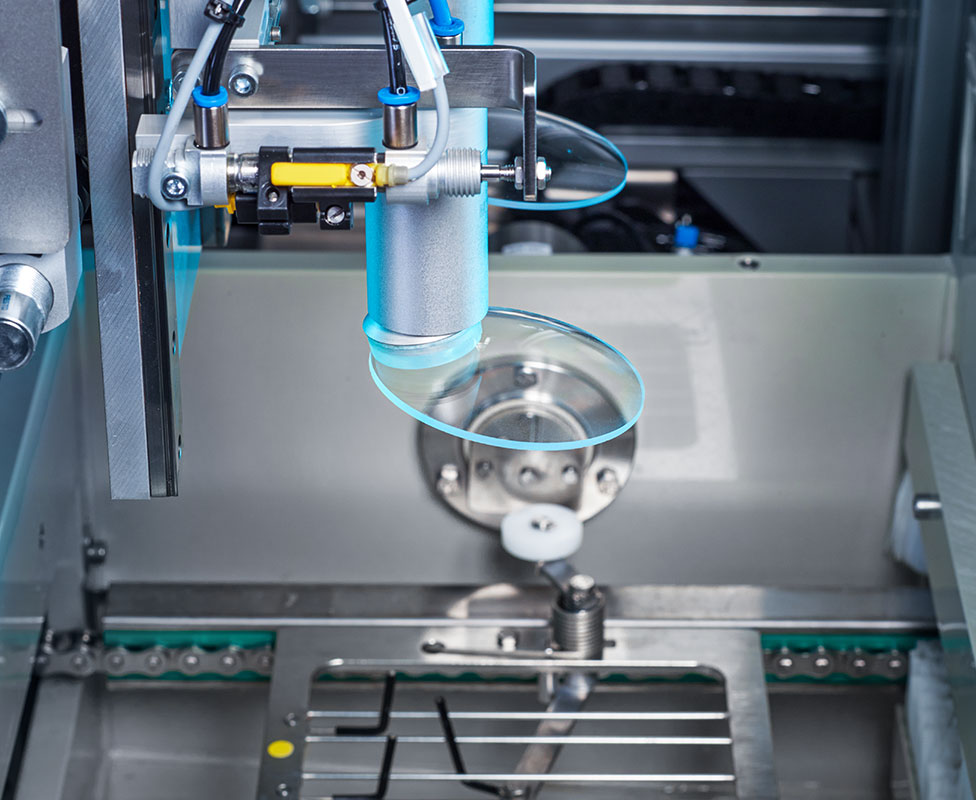

LCU Modulo ONE takes industrial cleaning to the next level, offering the same cleaning power as larger solutions but in a compact fully-automated inline unit. Utilizing the proven SCHNEIDER technology, it cleans both sides of the lens scratch and damage-free.

Full automation

LCU Modulo ONE comes with a loading and unloading robot on board.

The fast transfer of the lenses results in shorter cycle times and superior throughput.

New process logic

LCU Modulo ONE’s new process logic facilitates intense and thorough cleaning despite its compact design. Labs can choose between a two or three cleaning station setup plus drying station. The brush cleaner effectively removes even prints and adhesive residues, preparing the lens for dip or spin coating.

A sound investment

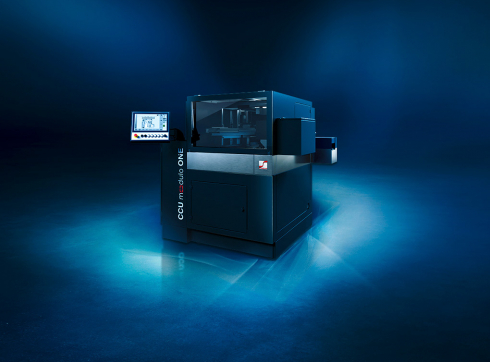

As an integral part of the one-of-a-kind Modulo system, the brush cleaner is subject of the centralized monitoring system, the Control Center.

Its affordable price and low cost per lens ratio make the LCU Modulo ONE a sound investment for any lab.

The Modulo advantage

LCU Modulo ONE comes with an on-board global interface philosophy that allows connection to the Modulo system.

Once connected to the Modulo system, the machine works as an integral part of this one-of-a-kind solution and is subject to the centralized monitoring Modulo Control Center. The lab manager is fully informed about the current status of the machine. Therefore critical situations and downtime

can be avoided before they arise. Higher uptimes and increased yields are guaranteed.

Watch LCU modulo ONE in action!

Benefits

Smallest footprint

Small investment, lowest cost per lens

Fastest cycle times

Cost effective

Special cleaner - one for all

Fully automated loading and unloading

Download

LCU modulo ONE

Technical Data

lens diameter

40 – 80 mm

lens material

all plastic materials

power consumption

9 kVA avg.

air requirement

6 bar (87 psi)

water requirements

DI-water conductivity < 1 μScm, 1 l/min

machine weight

approx. 985 kg (2172 lb.)

with automation: approx. 1300 kg (2866 lb.)

dimensions (width x depth x height)

approx. 2640 x 1260 x 1795 mm (104 x 50 x 71 inches)

with automation: approx. 3687 x 1488 x 1934 mm (145 x 58 x 76 inches)

Brochure LCU modulo ONE